Why? The ability to keep industrial operations at full speed while maintaining environmental compliance and limiting their impact on communities will be a core pillar of their success in years to come.

When environmental compliance obligations become overly rigid and cumbersome, operators are likely to lose the ability to make swift decisions in real-time. This hinders the ability to implement changes that boost efficiency gains when they are needed the most.

Making decisions confidently also relies on mining or industrial operators having accurate and up-to-date information at their fingertips. More than just having the data on hand, it needs to be quick and easy to interpret. Non-technical users need to draw deep, actionable insights that are relevant to that point in time to make decisions that matter.

Environmental intelligence helps operators not only stay on top of weather and emissions risk – but also stay ahead of potential issues in the future. Operational flexibility is one aspect of this, however mining and industrial sites can also use the power of hyperlocal weather and emissions forecasts to gain complete situational awareness of their entire site’s impact today, and tomorrow.

How does environmental intelligence provide operational flexibility?

Over the last 20 years, technology as we know it has advanced at an astronomical rate. What was highly innovative just a few years ago is now in many cases outdated.

Digital offerings within the field of environmental science continue to replace necessary yet manual processes that hindered productivity such as compliance reporting, environmental monitoring and local weather forecasts.

The data collection process has gotten much faster over the years. Rather than having to wait for the information they need to become accessible, companies can now instantly view and interpret real-time data when making operational decisions.

Today, environmental intelligence has made it possible for large mining and industrial facilities to collect, analyse and implement required operational changes from complex data on environmental parameters swiftly and effectively. Value beyond environmental compliance can be unlocked with fast, informed decision-making that enhances an industrial operation’s performance.

Operators now have a better understanding of their impact from the highly accurate, situational awareness that environmental intelligence provides. This offers greater flexibility and a better ability to enable rapid, confident response to environmental risk.

Activities can be scheduled at times of low weather risk to keep routine operations on schedule, defensible data can be used to satisfy regulatory requirements, quality of life can be improved for all employees and social license to operate can be protected.

1. Data and insights are clear, accurate and easy to understand with environmental intelligence

Data collection and reporting has historically been a labour-intensive process for environmental managers. The ability to convert this into meaningful insights to be of real value, a task that until only recently was extraordinarily cumbersome.

Paper-based approaches have hindered the ability of operators to make necessary adjustments in a timely manner. When it was time to bring these changes into action, local weather conditions have already changed. This makes decisions less likely to achieve efficiency gains or have a positive operational impact.

In the past decade, mining and industrial facilities have been able to leave this slow and rigid process well and truly in the past. Complex environmental information is now far easier to act on, even for those that do not have specialist knowledge or technical qualifications.

Data visualisation from environmental intelligence presents environmental information in a way that makes it quick and easy for experts and non-experts alike to monitor, manage and report on environmental parameters. Real-time data and hyperlocal weather forecasting improves the capacity to make critical decisions based on the current situation and what is projected to happen in the hours and days ahead.

If an incident occurs due to site-generated emissions or your operation receives a community complaint (e.g. a vibration or dust issue), this information makes it far less difficult to pinpoint what may have caused the issue so that a suitable plan for resolution can be put in place immediately.

The power of environmental intelligence goes beyond action on events that have occurred in the past. It makes it possible for operators to act with urgency and agility in response to or in a targeted effort to prevent emissions events from impacting the community again in the future.

2. Environmental intelligence provides faster incident resolution

Vibration and dust are almost always a by-product of routine operations associated mining and various industrial operations such as metal smelting, unloading of bulk cargo or haul road trucks. While at lower levels they are unproblematic, when thresholds are exceeded, issues can arise in the community.

If emissions incidents aren’t identified and develop into chronic or highly disruptive problems, pressure from environmental authorities, local communities and negative publicity can grow. This can leave any facility in the position where operations need to be temporarily shut down until the issue is rectified.

Unplanned stoppages and interruptions can have costly ramifications financially and on time-based resources. The longer it takes to identify and resolve the problem at hand, the more strain there is on community relationships as their trust in the sites ability to minimise emissions impacts diminishes.

Environmental intelligence enables flexible and agile response systems for site operators to make confident and considered decisions with the power of hyperlocal weather forecasting and highly accurate, predictive data on their site’s emissions impact.

Operators have access to accurate, real-time modelling and monitoring data from multiple parameters such as air quality and noise impact. With this information readily available, mining and industrial facilities can act on issues as fast as possible and minimise the impact in nearby areas, avoiding unplanned downtime while protecting their reputation and bottom line.

3. Plan ahead using environmental intelligence to determine the best course of action for an anticipated or existing incident

As emissions incident are unfolding, operators are under immense pressure to not only get the issue back under control as fast as possible but to also minimise any disruptions to usual operations.

Mining and industrial facilities can proactively manage emissions incidents such as dust or odour events with colour-coded insights using environmental intelligence.

At mine sites specifically, operational dust management strategies or Trigger Action Response Plans (TARP) rely on continuous, unattended monitoring of emissions risks. However, it can be difficult to act on static data without context.

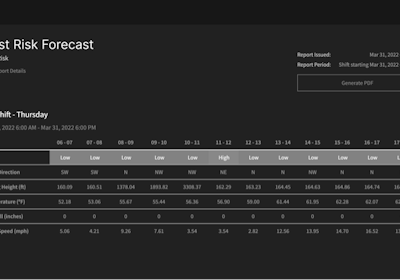

Predictive risk reports can provide a 72-hour window into the future for operators to plan for shifts with high emissions risks.

But when they can determine there is likely to be an incident before it occurs, there is more time to consider which approach will be the most effective and operators can get ahead of the problem – in some cases avoiding it from occurring altogether.

As a proactive approach, operators and mining and industrial facilities can access insights from combination of real-time dust monitoring hardware with local weather conditions. This information provides actionable insights for operators to mitigate unfolding emissions by visualising where they should focus emissions mitigation efforts. This allows for complete situational awareness of a mining operation at any given time.

Envirosuite’s EVS Omnis platform uses environmental intelligence to provide a 72-hour picture with hyperlocal weather and emissions forecasts for operational planning. Through leveraging this data, mining and industrial sites can optimise their operation and maintain compliance. Actionable insights mean they can plan ahead, rather than being caught out by unforeseen changes in the weather and potential emission events that can quickly lead to negative and costly consequences.

Operators are aware of which environmental risks to expect, which also gives them the ability to strategically schedule activities during optimum conditions to reduce community impact. An example of this would be planning maintenance activities, unloading bulk cargo or conducting blasting activities based on environmental factors such as weather to better manage the risks.

In addition, EVS Omnis provides high-definition, site-specific forecasts. With this information, mining and industrial sites can run multiple operational scenarios to determine which dust control strategies to mobilise at different times throughout particular shifts. Resource expenditure can therefore be lowered, as dust control and mitigation strategies can be implemented more accurately and effectively, as well as in a timelier manner.

When operators proactively manage risks using environmental intelligence they have more options for how to move forward. This gives them greater operational flexibility when it comes to finding and implementing a suitable resolution.

Envirosuite is revolutionising environmental intelligence for mining and industrial facilities

While operators can now use Envirosuite’s environmental intelligence to access rich real-time data, predictive modelling and quality insights to inform decisions are their facility, this wasn’t always the case.

Only a few years ago, diagnosing the source of an emissions incident was difficult and time-consuming. Now if operators receive a complaint about vibration or dust, they can quickly accept or refute responsibility and determine the cause without delay.

While technical environmental data and information have been complex and difficult to act on in the past, environmental intelligence software like EVS Omnis provides insights in a way that’s easy to understand and interpret by visualising data. This caters to experts and non-experts alike, so regardless of whether you are a specialist in the area you can make critical operational decisions swiftly and with confidence.

In addition, collecting meaningful data takes time. But when a complaint is lodged by someone in the community, rapid response is mission critical. It’s at these times that having all of the information needed to make an efficient and effective decision readily available is invaluable – and this has been made possible by environmental intelligence. Now, the data collection process is much faster and mining and industrial facilities can instantly view and interpret real-time data.

By harnessing the power of environmental intelligence, such as Envirosuite’s EVS Omnis platform, operators can access easy-to-understand, actionable insights on their site’s environmental performance. This puts them in a better position to protect their operations and people.

As a practical and user-friendly solution, EVS Omnis assists mining and industrial facilities with staying agile and flexible as environmental conditions change over time and present new challenges.

Contact us about environmental intelligence for mining and industrial facilities

Built on 30+ years of expertise, our software is trusted on a global scale. With Envirosuite’s environmental management software, you can collect and interpret complex data, address operational challenges and build trust with stakeholders.

Designed for rapid deployment, our monitoring and forecasting solutions can be implemented in as little as a few days. Contact us to talk with our team about your environmental intelligence requirements.