SeweX

Sewer network modelling software for proactive management of odour, corrosion and safety risks across entire networks.

Corrosion, odour, and safety issues related to methane and hydrogen sulphide in sewer networks

Wastewater networks are the source of odorous and hazardous gases generated by natural biological processes. Methane (CH4) and Hydrogen sulphide (H2S) not only have the highest risk profiles but also cause some major issues to most water and wastewater utilities.

This includes safety, customer satisfaction, operational costs and environmental footprint.

Introducing SeweX

Innovative sewer network modelling software to identify odour, corrosion and safety risks

SeweX was developed through advanced research and rigorous testing led by the University of Queensland and supported, validated by many major Australian water utilities. Today, SeweX is being adopted by many wastewater networks operators and utilities around the world.

SeweX uses sewer network, hydraulic network and wastewater quality data to model and predict where methane and hydrogen sulphide generation will occur, helping utilities decide the optimal strategy to prevent odour and hazardous gases from generating.

Quickly identify the root cause and drive down operating costs

The cause of odour and corrosion issues in the network can be quickly identified, together with an analysis of potential dosing strategies to minimise operating costs and extend the life of the network.

Better understand risks related to sulphide and methane

Odour, corrosion and safety risks related to sulphide and methane generation is also easily understood with network-wide mapping of risk.

Reduce the time to perform network analysis from years to days

Running scenario simulations reduces the time to perform network analysis from years and months to days, allowing utilities to make confident and quick decisions when planning capital works programs.

Backed by science and validated by water utilities

Developed through over 10 years of advanced research by the University of Queensland and validated by major Australian water utilities.

Inside the product

An intuitive heatmap of odour, corrosion and safety risks throughout the entire sewer network

While market alternatives offer only simple storage and display of monitoring information, SeweX provides rapid and thorough understanding of risk. SeweX develops and supports science-based decision making for short-term and long-term improvements.

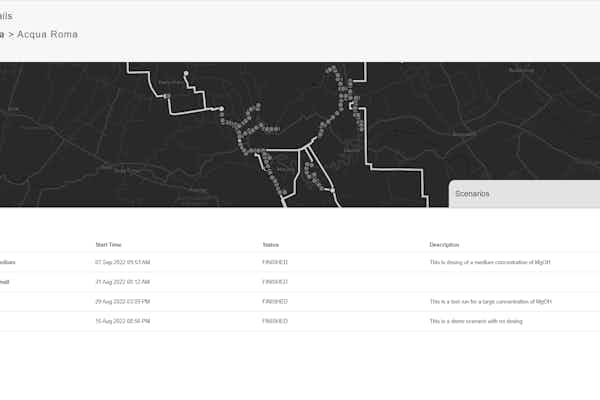

Run scenarios to ideate and test improvements

Multiple scenarios can be run based on changes to the parameters and then compared to the baseline simulation. This allows operators and asset owners to ideate and test improvements without having to make physical changes to the network.

Model physical, chemical and biological properties of sewer networks

Over 35 parameters are included in SeweX. Operators can select any of these parameters, such as hydrogen sulphide or methane, SeweX then - within seconds - calculates and displays a heatmap of the spatial results (concentration, location, etc.).

Allow operators to have a comprehensive understanding of their networks

From existing hydraulic network data, SeweX will generate a network representation showing nodes and conduits of the network. Operators can select a manhole or pump station to learn more about the current chemical dosing approach.

Customer service

World-class service and expertise

Operational and design data can be taken from the existing monitoring network or customer systems. On-site or web-based training is provided to every customer as part of subscription fees.

Ongoing support is provided via our 24-hour global support portal, which includes in-house water industry experts to guide you in the most efficient use of the system.

Learn more about SeweX case studies and latest insights

about your sewer inspection requirements and how our sewer network modelling software could help.