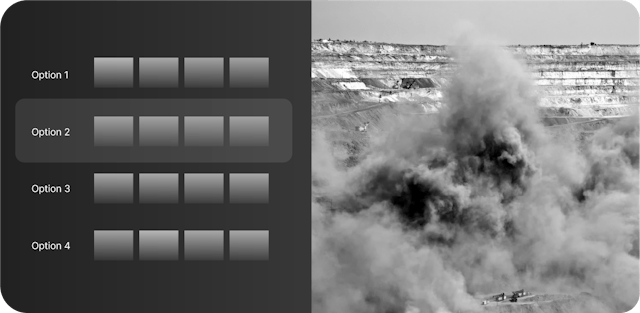

Dust monitoring that stops dust in its tracks

Dust can spell trouble

Keep operations on track 24/7 while staying compliant

Dust hazards can disrupt operations and strain resources, especially when suppression strategies aren’t targeted. Water is essential for dust control, but using it inefficiently in a blanket approach drives up costs. Our software gives operators real-time insights, combining hyper-local weather data with site-specific conditions to pinpoint exactly where and when suppression is needed—helping you stay compliant while optimizing resources.

Stay compliant with license conditions

We do more than just monitor dust—we tailor solutions to fit your unique operations. Our smart software helps you respond in real-time, using localized weather data to fine-tune dust control and keep your site running smoothly. With a clear view of risks across your facility and surrounding areas, you can protect your team, your community, and your bottom line.

Protect your team from dust-related risks.

Dust isn’t just a compliance issue—it’s a real threat to worker safety. Poor air quality can affect respiratory health, and low visibility creates serious hazards on site. Our smart software helps you stay ahead of these risks with real-time insights, so you can control dust before it impacts your people. With better suppression strategies and instant alerts, you can keep operations running safely while saving time and resources.

Switch to proactive dust management

Mitigating fugitive dust while improving operational performance is a fine balance. We help operators find and capitalise on this with highly advanced digital dust management.

Upgrade to 24/7 real-time and 72-hour predictive monitoring

No more ‘wait and see’. Be across non-compliance events minute-by-minute with our real-time monitoring. Tackle potential issues before they unfold with instant alerts and model different weather and operational conditions to optimise operations.

Backed by science. Supported by experts.

We combine groundbreaking hardware and software with our worldwide network of 250+ specialists. They’ll help you understand non-compliance risks across your site and give you tailored advice, strategies, resources and insights to mitigate or reduce them.

Reduce cost, resources and water involved in dust suppression

Optimise your dust mitigation strategies. No more excess water usage, potentially hazardous chemicals or increased risk to worker and community safety. Switch to site-specific dust suppression strategies that minimise cost, impact and shutdowns.

Quickly and accurately diagnose the cause of dust non-compliance

Confidently report the exact source of any non-compliance issues. Our property algorithms automatically analyse high readings on dust monitors to determine the cause and how best to mitigate the risks.

24/7 real-time insights and smart alerting

72 hour dust impact forecasts to schedule activities

Hyperlocal weather modelling to support event analysis

Operational guidance to targeted mitigation strategies

"We use Envirosuite across our business to support the world’s best practices in our mining and port operations enabling continued improvement in terms of our environmental, community and financial outcomes. I would recommend to my peers in other mining operations globally to consider adopting the platform to enable the improvement of critical controls and performance metrics."

COO, Cerrejón Mine

“17% drop in complaints”

Read the storyDust monitoring is our sweet spot

Avoid costly shutdowns and bad press. Take control of dust with smart technology that makes monitoring and management easier than ever.

Managing dust on mine sites is challenging without real-time data. A network of low-cost monitors across the site helps pinpoint dust sources, so operators can act before conditions escalate.

When dust events occur, mine operators need to respond fast while keeping production on track. Automated monitoring delivers instant, color-coded alerts, helping teams adjust suppression strategies, reduce disruptions, and stay compliant.

Managing air quality in industrial operations is complex, especially with multiple emission sources. A network of low-cost monitors helps operators track emissions in real time, pinpoint sources, and adjust activities to reduce impact before problems arise.

With automated reporting and predictive insights, teams can confidently respond to potential air quality risks, adjust schedules to minimize emissions, and stay ahead of compliance requirements. Real-time alerts and intuitive tools also make it easier to address community concerns and demonstrate responsible operations.

With so many emission sources at play, managing air quality at ports can be tough. Our real-time monitoring and predictive insights help you quickly spot problem emissions, adjust schedules for dusty activities, and take action before issues escalate.

Automated reporting and low-cost monitoring networks keep your team informed and ahead of compliance requirements. Plus, with intuitive tools and clear data, you can respond to community concerns faster and show your commitment to responsible operations.

Thinking, Research and News

Blog

Solving Dust Control Challenges at Mining Ports with Real-Time Environmental Intelligence

Blog

How much money do mines spend on dust control?

Blog

How can technology support TARPs for more effective dust control at mines?

Webinar

The 5 stages of Community Engagement every Industrial Operation must understand

FAQs

Here are answers to common questions about our dust management solutions. Reach out to our team today if you don't see the answer you are looking for.

Envirosuite goes beyond simple visualisation and basic dust monitoring applications. The power of Envirosuite is in the capture, storage and analysis of real-time data and forecasting abilities, giving it unique application to evolving operational issues. In addition to compliance, the user has powerful tools to respond quickly to alerts, minimise or avoid off-site impacts and hence, be a good neighbour.

Hyperlocal weather forecasting and real-time dust monitoring networks can play an essential role in supporting fugitive dust control strategies at industrial sites. By understanding weather patterns and how they can impact dust emissions, operators can integrate with their dust control measures to ensure that they are optimised for reducing the negative impact of emissions on public health and neighbouring communities.

Predictive solutions allow you to analyse scheduling plans in advance and get operational lead team to minimise costly stoppages (e.g. “We need an extra water truck.”). Any real-time dust monitoring systems you have in place can also validate any predictions.

This is ideal if your operation requires more time to set a plan before a fugitive dust event or you need forewarning by at least a few hours. Predictive dust management systems can provide confidence to set a robust plan using powerful range of options with advanced notice to enable preparations prior to the shift. You will be able to understand your dust risk is 8 hours in advance to plan for the next work shift.

Envirosuite solutions provides operational efficiency and cost savings for mining organisations. For example, traditionally mines will have dust management strategies, such as watering haul roads, operating to differing production rates or taking additional measures like standing up non-essential equipment such as dozers, or reducing the number of trucks in the hauling fleet, etc.

By having situational awareness at a granular level across the operations a mining operator can better target fugitive dust hotspot areas (e.g. haul roads, pits and tailings dam beaches) and optimise production while also saving on the cost of mitigation in areas where it is not needed.

Curious how Envirosuite can help your operations perform better?

Discover how Environmental Intelligence can help you go beyond compliance, make smarter decisions, and unlock your full operational potential.

Ready to talk?

Before the dust settles, act on it.

Don't let dust get on top. Change starts with a chat.