What Are TSP, PM10 and PM2.5?

Total Suspended Particulates (TSP)

TSP refers to the total mass of all airborne particles suspended in the atmosphere, regardless of their size. This includes a mix of fine, coarse and larger particles typically generated by mining activities such as blasting, crushing, haulage and stockpiling.

PM10

These are inhalable particles with diameters of 10 micrometres or less. PM10 can penetrate the upper respiratory tract and settle in the lungs, posing health risks, especially to site workers and nearby communities.

PM2.5

The most hazardous particulate fraction, PM2.5 comprises fine particles with diameters of 2.5 micrometres or less. Due to their size, these particles can reach the deepest parts of the lungs and even enter the bloodstream, increasing the risk of cardiovascular and respiratory diseases.

Why does particle size matter?

The smaller the particle, the greater its potential to cause harm to human health and the environment. Fine particles (PM2.5) not only present serious occupational health risks but also contribute to reduced air quality visibility and regional air pollution challenges.

Why These Metrics Matter in Mining

Mining operations generate significant levels of dust through activities such as:

Blasting and drilling

Crushing and screening

Ore transportation and haulage roads

Stockpile and waste dump management

Uncontrolled dust emissions from these activities can lead to:

Regulatory breaches resulting in fines or shutdowns

Occupational health risks including silicosis and chronic respiratory diseases

Community complaints and social licence impacts

Environmental damage through deposition on vegetation and waterways

By monitoring TSP, PM10 and PM2.5 levels in real-time, operators can stay within permitted limits, protect workers and communities, and plan operations to minimise dust impacts.

How Modern Dust Monitoring Systems Help

Advanced dust monitoring systems provide continuous, real-time measurement of dust concentrations onsite. This empowers mining operators to:

Monitor operational hotspots and proactively manage dust-generating activities

Receive real-time alerts when threshold exceedances occur

Predict and plan around weather-driven dust dispersion risks

Support transparent reporting for regulatory compliance and community engagement

Data gathered from modern particulate monitors feed directly into cloud-based platforms like Envirosuite’s Omnis, providing actionable insights through intuitive dashboards and predictive modelling.

Envirosuite’s Edge in Dust Monitoring

Envirosuite’s integrated dust management solutions combine precision hardware with intelligent software to deliver unrivalled dust monitoring and control.

Key features include:

Source Identification

Determine the likely source of dust events by integrating real-time measurements with meteorological data and advanced back trajectory modelling.

Smart Alerts

Automated, configurable notifications when dust levels approach or exceed defined thresholds, enabling immediate operational responses.

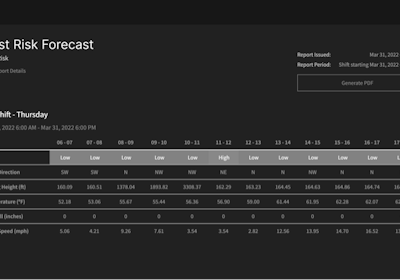

Dynamic TARP (Trigger Action Response Plan)

A live, site-specific decision support system that automatically triggers response actions based on real-time dust data and risk forecasts, helping prevent exceedances before they occur.

Forecasting and Dispersion Modelling

Predict upcoming dust risks based on weather forecasts and operational activity, allowing proactive scheduling of high-risk tasks during low-impact periods.

Hardware options include the Air Quality Monitor 5S and 2S, designed for harsh mining environments. These sensor-based stations measure multiple particulate fractions including TSP, PM10, PM2.5 and PM1 with proven accuracy and resilience. Data is transmitted wirelessly in real-time to the Omnis platform for visualisation, analysis and reporting.

Why Dust Management Is About More Than Compliance

In today’s mining industry, effective dust management is about more than just meeting compliance obligations — it’s about protecting people, strengthening operational resilience and maintaining trust with surrounding communities.

Understanding and managing key dust metrics like TSP, PM10 and PM2.5 is fundamental to achieving this.

Envirosuite’s advanced dust monitoring solutions provide the real-time insights, predictive capabilities and decision support tools needed to stay ahead of dust risks and operate responsibly.

Ready to future-proof your mine’s dust management strategy?

Book a demo with our team today and discover how Envirosuite can support your site-specific challenges.