The Real Challenge of Noise Compliance in Mining

Mining sites generate a range of noise types—from continuous mechanical hums of rock crushers to sudden, high-impact blasts. Left unmanaged, these noises can carry well beyond the site, disturbing nearby communities and triggering complaints, protests, or even regulatory intervention.

Beyond community impact, noise poses serious health risks to workers. Prolonged exposure to high noise levels may result in permanent hearing damage. Disruptive acoustic environments also reduce operational efficiency, leading to miscommunication, errors, and increased accident risk.

From a compliance standpoint, regulations often demand rigorous noise monitoring, accurate source attribution, and timely reporting. Unfortunately, traditional monitoring systems struggle with issues such as equipment reliability, false alerts, and irrelevant data from external noise sources, making accurate reporting and timely decision-making difficult.

Introducing Omnis by Envirosuite: Real-Time Intelligence for Noise and Vibration Monitoring in Mining

Envirosuite’s Omnis platform is specifically designed to overcome the limitations of conventional monitoring systems. It enhances noise and vibration management for mining and industrial operations through compliance-grade hardware like the EMU and VMT, paired with cutting-edge software analytics.

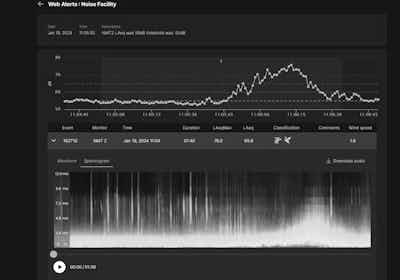

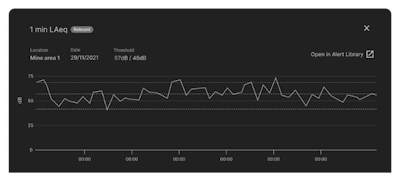

At the heart of Omnis is its ability to provide real-time, actionable insights. Alerts are configured to the site’s specific compliance criteria and are filtered to remove irrelevant noise sources such as wind or distant traffic. This helps environmental managers focus on what truly matters—events that could impact compliance, safety, or stakeholder confidence.

With instant audio playback and event classification, users can quickly determine the source of an alert and whether it warrants action or not. This prevents unnecessary disruptions, reduces downtime, and streamlines reporting processes.

Managing Multiple Types of Mining Noise Events: A Sophisticated Approach

Noise in mining isn’t one-dimensional. Environmental managers using Omnis can identify and respond to various types of noise:

Impulse noise from blasting can be monitored in real-time to prevent harmful exposure and avoid exceeding compliance limits.

Fast and slow noise associated with heavy equipment operation is continuously assessed to understand noise patterns and evaluate long-term mitigation strategies.

Omnis enables operational teams to link noise events with on-site activities. This correlation dramatically improves accuracy in reporting and root-cause analysis.

Omnis in Action: Filtering the Irrelevant and Highlighting What Matters

A key innovation within Omnis is its advanced alert system, which helps users avoid “alert fatigue.” In contrast to legacy systems that generate alerts for every minor fluctuation, Omnis uses intelligent rules based on both noise levels and environmental conditions, such as wind or rain. These rules prevent false positives while ensuring meaningful alerts are never missed.

For example, if a high noise level is detected but coincides with wind speeds over 5.5 m/s, Omnis can classify it as residual noise—avoiding unnecessary follow-up. Similarly, when multiple monitoring points detect high levels simultaneously, the system prioritises alerts based on likely operational causes.

This tailored approach means users can be confident that any alert they receive is relevant, urgent, and backed by data.

Protecting Social Licence and Building Community Trust

Noise from mining operations is one of the most frequent sources of community complaints. With Omnis, mining companies can implement proactive noise management plans and maintain transparency through accurate, reliable reporting.

By clearly demonstrating when noise levels are within legal limits and quickly addressing incidents when they’re not, operators can reduce complaints and build long-term community trust.

Supporting Health, Safety and Noise Compliance in Mining

Omnis is also instrumental in occupational health and safety initiatives. Data collected can be used to drive hearing conservation programmes, inform work rotation schedules, and support training initiatives.

Moreover, Envirosuite’s platform is aligned with regulatory standards and offers robust reporting features that make it easier to demonstrate compliance to authorities. With predictive alerting capabilities, operators can be warned of impending exceedances before they happen—giving them time to act and avoid costly penalties.

The Future of Noise and Vibration Monitoring in Mining

Envirosuite continues to evolve its technology, incorporating weather forecasting, predictive analytics, and new sensor types to enhance monitoring further. By combining noise and weather data, Omnis enables more reliable decision-making, helping mining operations operate efficiently without breaching environmental or social thresholds.

Ready to Enhance Your Mine’s Environmental Performance?

Discover how Envirosuite can help. Book a demo today.