Mining is one of the oldest and most essential industries in the world. It has helped build and sustain some of the most vibrant economies across the globe. However, it also comes with its challenges, including the generation of excess fugitive dust from operations, including silica dust, which can have significant impacts on workers' health and wellness. Fortunately, there are digital solutions available to make it easier for operators to manage this issue.

Let’s explore three ways technology can help manage fugitive emission sources and silica dust in mining operations.

1. Implementing denser dust monitoring networks: Enhancing compliance monitoring data with lower cost sensors

The first and most critical step to managing fugitive emission sources and silica dust in mining is to monitor their levels accurately. Besides the health risks, silica dust can also clog machines and other equipment, causing breakdowns and costly repairs.

Effective fugitive dust control at mining operations requires detailed information, specifically how to focus the action efficiently on the cause of the problem. Problematic levels of dust particles can be invisible. They are often highly variable over time and their impacts strongly depend on weather conditions. In all cases, knowing the scale of the problem needs measurement and analysis. The ability to avoid future problems needs much more sophisticated information on emission source behaviour and meteorology.

Increasing importance is placed on data from compliance monitoring at mine sites to limit impact across multiple parameters. However, unforeseen weather changes still make it difficult to mitigate dust events without halting operations or slowing production. Operators today face challenges optimising expenditure on mitigation resources and implementing TARPs using static data in paper-based reports.

A real-time dust monitoring system equipped with compliance monitors and additional an air quality sensor network can help accurately measure silica dust levels by providing more detailed. This real-time data can help supervisors or operators adjust workflows and equipment usage patterns to minimize dust generation while maintaining mining productivity.

In addition to managing risk for silica dust in mining, there are numerous operational benefits that environmental intelligence can bring to dust monitoring networks at mine sites.

2. Identifying risk of silica dust in mining with smart alerts: Limiting impact on workforce and equipment

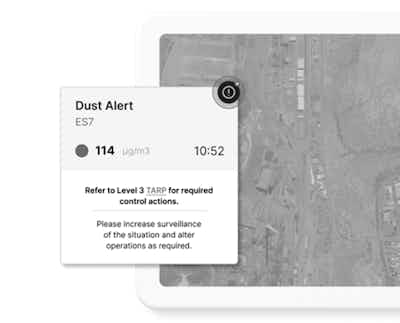

Digital solutions are now assisting operators to achieve operational flexibility within environmental constraints. Real-time operational guidance and smart alerting can help identify high risk events in advance while understanding the root cause of issues.

Environmental intelligence technology not only supports monitoring of dust levels in real-time but can also transmit this data to various stakeholders in real-time. This information can be accessed via mobile devices, desktop computers, or APIs from locations outside of the mining site. This helps supervisors and safety professionals respond to any detected spikes in silica dust levels quickly. They can take immediate action to mitigate the risks, ensuring the safety of all workers involved.

In addition, the ability to configure smart dust monitoring systems with descriptive prompts on recommended actions can help deliver an early warning of events and easy analysis of past events. This can help operators manage silica dust in mining and report on the information required by regulators, but also allow non subject matter experts to mitigate emissions risks effectively.

For instance, the right alerts can remind operators when they need to be concerned about lack of dust mitigation resources due to dry weather conditions, or when to conduct silica dust generating activities at times of low risks. Operators can ultimately prevent noncompliance and limit impact on workforce.

.png?auto=format,compress&cs=tinysrgb&fit=crop&crop=focalpoint&fp-x=0.50&fp-y=0.50&fp-y=0.1&w=400&q=25&blur=5&sat=-100)

3. Predictive insights and hyperlocal weather forecasts: Targeted fugitive dust abatement across the site

Mining operators can predict future fugitive dust events using hyperlocal weather and emissions forecasts that have become a key part of Environmental intelligence technology. These insights can also help operators gain operational lead time and schedule operations at times of low risk to avoid impact on workforce.

As a proactive approach, operators and mining operators can access insights from combination of real-time dust monitoring networks with local weather conditions. This information provides actionable insights on fugitive dust for operators by visualising where they should focus emissions mitigation efforts and alert workforce of potentially high risk at any given time.

.png?auto=format,compress&cs=tinysrgb&fit=crop&crop=focalpoint&fp-x=0.50&fp-y=0.50&fp-y=0.1&w=400&q=25&blur=5&sat=-100)

Making informed decisions to control fugitive dust sources and silica dust in mining

Managing fugitive emission and silica dust in mining is a crucial aspect of responsible operations. However, with environmental intelligence technology, mining operators can take proactive steps to ensure the safety and health of their workers while minimising equipment breakdowns and costly repairs. Furthermore, environmental intelligence technology's real-time data access and predictive insights can help supervisors make informed decisions to maintain productivity levels while minimising silica dust exposure. Overall, the benefits of environmental intelligence technology make it a valuable tool for any mining operation looking to balance safety, productivity, and profitability.

Talk to us about your silica dust in mining requirements today

Envirosuite understands the importance efficient and sustainable mines play in society. Our digital solutions help a growing number of mining operators around the world to:

Gain operational flexibility to maximise productivity while remaining compliant.

Support TARP across multiple parameters and reduce safety risks.

Demonstrate responsible operations and build social license to operate.

Contact us today.

.png?auto=format,compress&cs=tinysrgb&fit=crop&crop=focalpoint&fp-x=0.50&fp-y=0.50&fp-y=0.1&w=400&h=280&q=25&blur=5&sat=-100)