Blast

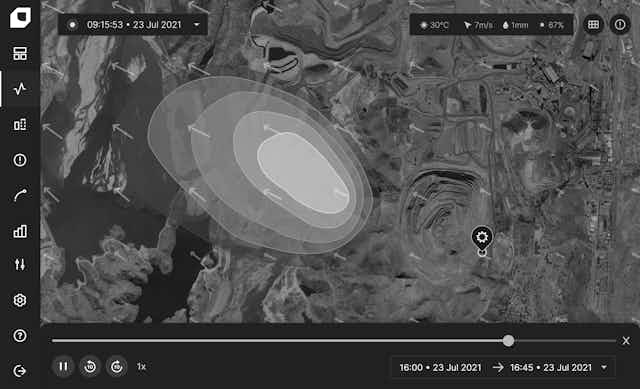

Predictive blast management solutions for operational mining blasting personnel to avoid impact from overpressure and dust fumes.

Blast Planning

Miscalculating the weather during blast management can cost you big time

Travelling blast fumes and dust emissions can lead to serious fines and regulatory penalties. Understanding the optimum time to carry out blasting operations is mission critical.

Our Blast Planning solution lets you know when you should be blasting and what impact it will have on your mine, outside of your boundaries and or on any surrounding communities.

Product features

Blasting solutions that pinpoint the best weather conditions to detonate

Open-cut mining operations are constantly faced with the challenge of conducting mining blasts that maximise production but also minimise impacts on their workforce and surrounding areas

Our Blast Planning solutions allows blasting operators to plan blasts at the optimum time to ensure they avoid impacting the community.

Make better decisions around blast management

Adjust your operations with certainty based on environmental events that you are problematic.

Visualise the direction blast fumes will travel after detonation

Keep operations at full speed when you know there is a low risk of breaching compliance or impacting the community.

Model dust fumes, flyrock, overpressure and vibration

Control operational output by understanding when the best time is to blast and when you should schedule other operational activities.

Avoid regulatory fines and positively impact your bottom line

Increase production levels by planning activities ahead of weather events to avoid fines and costly stoppages.

Inside the product

Intelligence to avoid compliance breaches and operational stoppages from open-pit mining blasting activities

It’s difficult to undertake blast management at mine sites using historical data. Understanding blast fume impact in real-time is key to limiting stoppages.

Run multiple blast management scenarios with site-specific weather data

Plan ahead and easily predict your fume and overpressure impacts so you don’t disrupt operational activities and so any communities surrounding don’t feel the blast too.

Protect your social licence and avoid impacting communities

You will be able to highlight proactive efforts in reducing your footprint and operating responsibility by avoiding negative impact on surrounding communities.

Prepare operational teams for dust, vibration, flyrock and overpressure risks

Prepare your team before blast management activities are conducted to avoid workplace incidents, reduce stoppages and keep your site safe.

RECOMMENDED PRODUCTS

Other EVS Omnis products you may be interested in

Customer service

World class service to help your site get up and running quickly

Our team of specialists will work with you to address your site's specific requirement. We can answer questions you may have about operational or environmental challenges you may be experiencing at your site.

We can make recommendations for third-party hardware our we can hook directly into pre-existing environmental monitoring and sensor networks at your site. Our platform is 'sensor-agnostic'.

Catch up on the latest insights for all things Omnis Blast Management

about your mining blasting requirements.