The costly consequences of unplanned stoppages from vibration impact

Today Industrial operators are under growing pressure to improve efficiency and increase productivity while staying compliant to strict environmental compliance requirements.

The need to identify when things are starting to go wrong and act on potential issues quicker has only become more important due to increasing pressure from environmental authorities and local communities.

Management of open-pit mining operations or large construction projects is full of complexities, which makes it all the more necessary to have sufficient systems in place for monitoring and managing risks. This includes those associated with multiple environmental parameters, particularly vibration.

Non-compliance with local environmental regulations, interruptions and stoppages can all too easily become a litigious nightmare. This can result in reputational damage in the community and costly delays for operators — ranging from hours to days or even weeks.

In addition to lost revenue and lower productivity, it’s important to note that the slightest of operational disruption could risk projects to go over budget. The longer it takes to pinpoint and resolve a problem, the more deadlines are disturbed and harder it becomes for the ground staff to get operations back on track.

Avoiding unscheduled downtime with alerts from vibration monitoring systems

In a time where industrial sites are located close to growing communities, it has become challenging to strike the balance between productivity and environmental compliance.

When site operators proactively work to stay ahead of risks — using real-time data and reporting — they can leave reactive or chaotic responses while under the pressure of a shutdown in the past. The operations team also benefits from fewer safety risks and less stress while surrounding communities aren’t directly impacted by breaches.

With a systematic and reliable approach from the get-go, it’s possible to avoid the need to press pause on operations and to dodge costly hold-ups. In the context of environmental risk management, vibration monitoring software is a practical solution for businesses looking to maximise efficiency and minimise unplanned stoppages.

Often vibration is accepted as an inevitable by-product of mining or industrial operations. However, when vibration levels can exceed strict compliance limits imposed there are financial penalties from local environmental authorities. Construction projects or industrial operations without a monitoring system in place often run the risk of structural damage to sensitive equipment and buildings in the neighbouring communities

This is where continuous vibration monitoring systems become a key operational tool. Operators can ensure proactive management of risks that come hand-in-hand with vibration. This puts the facility in a better position to operate within thresholds, comply with regulatory standards, satisfy stakeholders, pinpoint unfolding issues in real-time and minimise unplanned stoppages.

Taking a closer look at vibration monitoring software: EVS Omnis

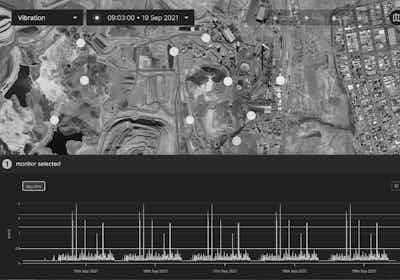

EVS Omnis is equipped with vibration monitoring solution that is built for today’s dynamic operating environment. It enables operators to manage multiple environmental parameters including vibration with complete situational awareness of their site. The platform displays real-time monitoring data in an easy-to-use, colour-coded dashboard for better operational decisions.

With EVS Omnis, site operators receive an alert when there’s a potential breach in vibration threshold. The platform aids in the early detection of problems, so you can act rapidly and get on top of the issue before it progresses any further. Often this means impact can be kept to a moderate level, rather than potential catastrophic consequences that lead to damage to nearby buildings or human health.

When operational teams have all the information ahead of time, they aren’t under the pressure of getting operations back up and running as soon as possible. Instead, operations can be strategically scheduled to minimise unscheduled downtime.

EVS Omnis also helps operators conveniently engage with stakeholders using public portals, so community members can submit vibration observations or concerns directly. Many communities value transparency and EVS Omnis offers visibility into environmental performance of your operation.

Automated compliance reporting is another effective and convenient way EVS Omnis can be used to ensure all stakeholders can view relevant vibration data in a simple and easy to understand interface.

EVS Omnis real-time vibration monitoring solution

Envirosuite’s practical vibration monitoring solutions

If your approach to environmental management is falling short, Envirosuite’s real-time vibration monitoring software could be the solution. EVS Omnis is trusted on a global scale and can be seamlessly implemented in open-pit mining operations, construction projects and industrial facilities.

Contact our team today about minimising unplanned stoppages at your operation with EVS Omnis vibration monitoring software.