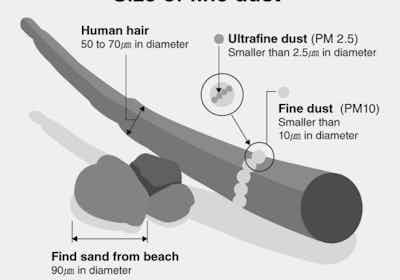

The smallest coal dust particles go down to about 1 micron in diameter. To put this in perspective, a typical human hair is about 70 microns across. So how does such a tiny particle cause such a huge issue?

Recent reports of workers suffering from dust-related illnesses in Queensland have led to questions around health and safety in mines. Potentially fatal diseases can be caused by long-term exposure to high concentrations of dust generated during some mining activities if there is inadequate worker protection.

In response, the Queensland Government has legislated to fine mining companies up to $4 million AUD if their workers are adversely affected by dust.

The image above shows a human hair compared to dust particulates courtesy of US EPA.

However, compared to 100 years ago, today’s mines are highly efficient and safe operations. Millions of dollars are spent every year by mines - particularly on water and personal protective equipment - to mitigate dust impacts to protect workers and remain operationally efficient. Water and dust suppressants can impose a substantial financial metric on operations due to its use in controlling airborne dust.

Processes that cause dust exposure for workers

In addition to natural weather influences, there’s a range of operational activities that create airborne dust. Heavy vehicle movements and blasting are a necessary part of open-pit mining operations. Today’s mines have strict HSE processes around the best time to blast to ensure safety and limit impacts. Haul trucks are also known as having the largest potential impact to stir up dust through routine transportation and loading activities. However, a difficulty when dealing with dust is determining what happens over the hours after dust-generating activity takes place.

Once in the atmosphere, coal and other dust particles are at the mercy of gravity and the wind. Larger particles settle back to the ground more quickly than finer ones. Finer dust particles can remain airborne for hours and are dispersed by the wind and turbulent eddies kilometres from their source.

.jpg?auto=format,compress&cs=tinysrgb&fit=crop&crop=focalpoint&fp-x=0.50&fp-y=0.50&fp-y=0.1&w=400&q=25&blur=5&sat=-100)

Finer dust particles from blasts at coal mines can remain airborne in the atmosphere for hours after detonation.

This can put mineworkers at risk from exposure as it may be difficult to tell when the dust has dispersed sufficiently without effective monitoring and management. Dust monitoring provides the benefit of seeing the real-time and historical picture, but the drawback of not offering insight into what will happen in the future. This deficiency of monitoring-only solutions can make it hard for teams to pick the right approach to mitigation.

Using predictive dust modelling to mitigate risk on mineworkers

Science and technology provide the way forward for effective forecast predictions that can help take action on potential dust issues before they occur. Envirosuite marries site-specific weather forecasts with environmental data from real-time monitoring stations and information from the mine plan to provide operations with actionable insights for dust risk mitigation.

The image above shows Envirosuite's 'Blast Management' solution being used to predict the direction of blast fumes will travel.

For example, the prediction of blast fumes and dust using sophisticated models that give fast answers now allows teams to understand the direction the plume will travel after the blast and the concentration levels of dispersing dust plumes. Operators are able to plan ahead and avoid worker exposure to airborne dust from blast fumes with more confidence.

In another application, predictive modelling provides operators with a picture of how the weather will affect airborne dust from the many different areas of the operations. Automatically generated predictive reports can detail dust risks at every hour of the next few days and link the risks with site-approved actionable responses to enable operators to act ahead of an issue and avoid a problem rather than after an impact has occurred.

Mining operations are able to use these insights to know when increased risks are expected, the reasons for the increased risk and what to do about them.

The image above shows a predicted dust risk report for worker shifts produced by Envirosuite's 'Risk Management' solution.

Limit exposure to coal-dust at your mine today

Find out more about how Envirosuite helps you make smarter and faster decisions at your mine to protect your most valuable asset - your team.

Discover Envirosuite's predictive dust management solution for coal mines here.