Particulate matter (PM) in the air comes in many types and sizes.

All can be highly problematic for various reasons by causing breathing problems or skin irritations from particles such as crystalline silica. Other dangerous gases like nitrogen dioxide (NO2) and sulfur dioxide (SO2) are also common within dusty atmospheres.

Ultimately, understanding the risks associated with dust events will help keep workers both healthy and productive onsite, while minimising impact offsite. Yet, today’s operators also face challenges optimising expenditure on mitigation resources and implementing Triggered Action Response Plans (TARP) using static data in paper-based reports.

When dealing with unique hyperlocal weather conditions at mine sites such as wind speed and direction, ambient temperature, and humidity it can be difficult to determine when to engage control measures. Today’s air quality compliance solutions tend to be heavily geared towards regulatory grade monitoring equipment. Regularly monitoring dust levels with compliance monitors are now commonplace on most sites.

However, static data doesn’t provide enough context and can lead to blanket approaches using costly mitigation resources such as water trucks, dust suppressant chemicals and wind barriers.

Let’s explore a few digital innovations that can help.

Hyperlocal Weather Forecasts: Operate to Capacity with Conditions Such as Temperature Inversions

Hyperlocal weather forecasting leverages data from multiple sources such as weather sensors, satellite images, and AI algorithms, to provide weather forecasts on a much more granular level. With this technology, mining operations managers can anticipate wind speeds, direction, and humidity changes in real-time, enabling them to mitigate dust before it becomes a problem.

A digital weather forecasting system provides site-specific data that helps mining companies understand exactly when dust conditions are likely to occur. With this information, dust suppression resources can be deployed more efficiently instead of taking costly blanket approaches. Predictive insights on meteorological conditions from the mine site and surrounding areas can help anticipate future weather conditions, providing more time to deploy dust suppression resources.

Operators can use hyperlocal weather insights to plan for conditions that may be entirely unique to their site such as dust clouds from temperature inversions due to dry conditions, or periods of rainfall that may assist mitigation if it affects the right areas. These insights can help prevent unnecessary resource deployment, saving time and costs for the mining operation.

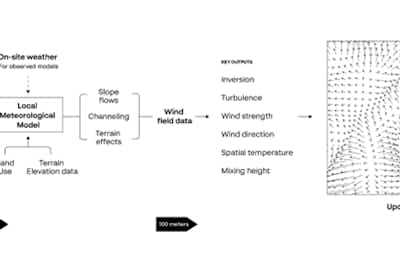

For example, Envirosuite’s Metriqa weather feed combines best-of-class meteorological models and hyperlocal forecasts to provide highly accurate decision support to users through the innovative capabilities of the Omnis platform. An diagram of how this works is shown below:

Hyperlocal weather forecasts assist confident operational decisions with a high-level of accuracy based on dependable hourly model runs at a 3km resolution

Insights from Mining Dust Management: Respond to TARP and Reduce Emissions Control Costs

Additional real-time dust monitoring sensors can be deployed after regulatory compliance networks have been established to provide immediate operational value when visualised across the site in parallel with site-specific weather conditions.

Operators can use this to create dense, real-time dust monitoring networks across the mine site and outside boundaries to provide comprehensive visibility into their processes. Real-time monitoring and visualisation capabilities can help mining operation managers identify potential hotspots for fugitive dust events that may affect their compliance. Smart alerting notifications can be tailored to their licence conditions helps them take proactive measures to mitigate it before it becomes a problem.

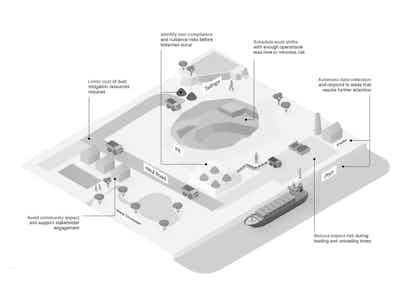

The image above shows examples of how digital solutions are providing mines with operational ROI on their dust monitoring efforts.

Operations managers can now use digital solutions to access actionable insights into how their teams are deploying dust mitigation resources, how effective they are, and where hotspots are. This capability can enable them to fine-tune their processes continually, achieving better performance over time.

Predictive Analytics: Gain Operational Lead Time from Mining Dust Management to Schedule Operations for Efficiency

Historically, PM data has been hard to obtain in sufficient quantity and quality to enable cost-effective real-time action. Costs and technological limitations have meant fewer and less timely dust measurements than are needed for such a purpose. Fortunately, these limits are being challenged by technological advances that mean the quantity, quality and timeliness of data are much better suited to real-time and predictive action.

The ability to identify correlations between weather conditions, operational variables from mine-sites, and dust accumulation can help operators determine when and where high dust concentration may occur. Predictive analytics are now enabling mining operations to get ahead of harmful dust levels before impact occurs.

Combining emissions modelling and hyperlocal weather forecasts to plan activities ahead of time can provide a 72-hour window into the future to schedule operations activities. The right amount of lead team can help minimise costly stoppages such as the need for extra water trucks. Any real-time monitoring in place can also validate any predictions.

Predictive analytics can help mining operators identify efficiency gains and obtain more lead time to minimise impact.

In conclusion, digital solutions are transforming how mining operations managers manage dust control in open-pit mines. These solutions provide hyperlocal weather forecasts, predictive analytics, and operational visibility for compliance, enabling them to allocate resources more effectively, monitor dust levels in real-time, and get ahead of potential hotspots. Invest in digital solutions that offer these capabilities, to make a significant difference in dust control and management of their resources.

Balancing Operational Efficiency, Compliance and Production at Today’s Mining Operations

Due to mounting pressure on mines to demonstrate responsible operations, increasing importance is placed on data from compliance monitoring to limit impact across multiple parameters. This has led to a constant struggle of balancing productivity targets against compliance thresholds and unwanted impacts. Today’s operators remain focussed on staying within imposed limits to avoid costly stoppages. Despite these measures, this can hinder efficiency by operating below optimal capacity.

Envirosuite’s Omnis platform is a cloud-based environmental management software built for today’s mining industry. The software enables site operators to act on insights from continuous dust monitoring systems. It can also be configured to trigger alerts in case of threshold exceedances, enabling operators to take proactive measures for dust mitigation.

Find out how Omnis solutions for proactive environmental management enables open-pit mining operations to:

Gain operational flexibility to maximise productivity while remaining compliant

Support TARP across multiple parameters and reduce safety risks.

Demonstrate responsible operations and build social license to operate.