Understanding TARPs: Comprehensive risk management for dust control at mine sites

Dust can wreak havoc on mine sites, creating health hazards and operational slowdowns. But what if there was a way to predict and prevent these disruptions? Trigger Action Response Plans (TARPs) are essential tools for mine operators, serving multiple critical functions. Think of TARP as a pre-programmed defense system against dust. By continuously monitoring dust levels through a network of sensors, the TARP identifies potential problems before they escalate.

This proactive approach empowers mine operators to adjust operations, deploy dust suppression methods, and keep everyone informed. By taking control of dust management, TARPs safeguard workers' health, minimise environmental impact, and keep mine sites running smoothly. TARPs are essential tools for mine operators, serving multiple critical functions. It's a smarter way to keep the dust settled.

Why It's time to rethink dust management strategies

Dust storms at mine sites are more than just an annoyance – they pose health risks and disrupt operations.

Traditional monitoring relies on static data, making it difficult to react quickly. Traditional methods of managing dust at mine sites often encounter several challenges:

Ineffectiveness: Traditional dust management techniques, such as water spraying or chemical dust suppressants, may not always effectively control dust emissions, especially in windy conditions or with certain types of terrain.

Resource Intensiveness: Many traditional dusts control methods require significant resources, such as water for dust suppression or frequent maintenance of roadways. This can result in high operational costs and environmental impact, particularly in areas where water is scarce.

Limited Effectiveness in Remote Areas: In remote or inaccessible mining sites, implementing traditional dust control measures can be challenging due to logistical constraints and limited infrastructure.

Regulatory Compliance: Compliance with increasingly stringent environmental and occupational health regulations poses a challenge for mine operators relying solely on traditional dust management approaches. Failure to meet regulatory standards can result in fines, legal liabilities, and reputational damage.

Maintenance Requirements: Some traditional dust control methods, such as road watering, require frequent maintenance and monitoring to remain effective. This can be labor-intensive and may distract resources from other critical operational tasks.

Seasonal Variability: Dust emissions at mine sites can vary seasonally, with factors such as weather conditions and operational activities influencing dust generation. Traditional dust control methods may struggle to adapt to these fluctuations effectively.

Harnessing Technology's Potential in Mine Operations

Technology plays a pivotal role in modernising dust monitoring at mine sites, offering numerous benefits over traditional methods. Advanced sensors and monitoring systems provide real-time data on dust levels, enabling immediate response to fluctuations and potential hazards. Continuous surveillance ensures comprehensive coverage of mining operations, while sophisticated data analytics tools analyse large volumes of monitoring data to identify trends, patterns, and risks. Remote monitoring capabilities allow operators to track dust levels from anywhere, facilitating timely intervention even in remote areas.

Automated systems can trigger alerts when predefined thresholds are exceeded, enabling rapid response to mitigate dust-related issues. Integration with other operational systems provides a holistic view of environmental conditions, while predictive modeling techniques anticipate future dust emissions, enabling proactive measures. Overall, technology enhances dust monitoring capabilities, improves operational efficiency, minimises environmental impact, and ensures regulatory compliance in mining operations.

Revolutionising dust management with advanced capabilities

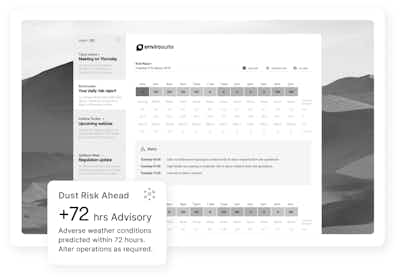

Introducing innovative solutions is paramount in addressing dust management challenges, with Envirosuite's Omnis platform leading the charge. Omnis employs a network of sensors to monitor dust levels continuously. When thresholds are exceeded, smart alerting capabilities can promptly identify sources and notify personnel. Here are some key capabilities of Omnis:

Real-time Monitoring: Omnis provides real-time data on dust levels, allowing for immediate response to fluctuations.

Precise Identification: Smart alerts accurately pinpoint the sources of dust emissions, enabling targeted intervention.

Weather Forecasting Integration: Omnis integrates weather forecasting, providing 24/7 real-time and predictive insights into how weather conditions may impact dust dispersion and allowing for proactive measures to be taken.

Data-Driven Decision Making: Armed with real-time data, operators can swiftly adjust operations or deploy suppression methods to preempt issues.

Proactive Risk Mitigation: Omnis' data-triggered responses empower operators to proactively mitigate dust-related risks, minimising environmental impact and safeguarding worker health.

Regulatory Compliance: By ensuring prompt response and intervention, Omnis helps ensure strict regulatory compliance, protecting against fines and penalties.

This proactive approach, driven by Omnis' advanced capabilities, not only enhances operational efficiency but also fosters a safer and more sustainable mining environment.

Talk to us today about how your mine can take the next step.