Customer Stories

Moving up on responsible mining index with the power of environmental intelligence

The mining giant in South America was able to stay ahead of its production targets while demonstrating sustainable and responsible mining operations to stakeholders.

The mine is owned and operated by a large Mining corporation. It is located in South America and is a large open-pit surface coal mine with peripheral operations such as coal transportation via and integrated shipping port terminal.

Region

Industries

Platforms

Challenges

Since the beginning of mining operations at the site, the most critical challenge has been to operate a large open-pit mine while complying with local regulations and incorporating international standards and responding to the expectations of neighboring communities in the region.

As productive as operations are, the mining site is environmentally constrained and is frequently challenged with unplanned stoppages due to air quality, dust, water and vibration impact to the surrounding communities. The facility needed a solution to monitor multiple environmental parameters in real-time and minimise its expenditure on emissions mitigation and reduce operational downtime.

Our relationship with Envirosuite has grown over time to the point where the platform is now an integrated part of our operations. We use Envirosuite across our business to support the world’s best practices in our mining and port operations enabling continued improvement in terms of our environmental, community and financial outcomes. I would recommend to my peers in other mining operations globally to consider adopting the platform to enable the improvement of critical controls and performance metrics.

- COO, Mining Operation

Solution

The mine operator worked with Envirosuite to deploy EVS Omnis across the site. The platform ingested data from compliance grade monitoring instrumentation across multiple parameters including local weather, air quality and water quality. The initial stages of the project involved real-time monitoring and analysis of the data to create and support a targeted action response plan (TARP) across mining operations.

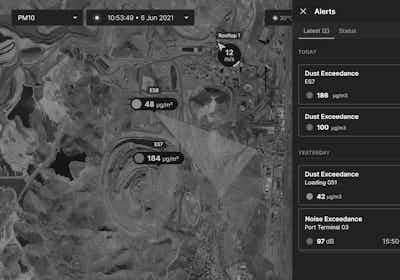

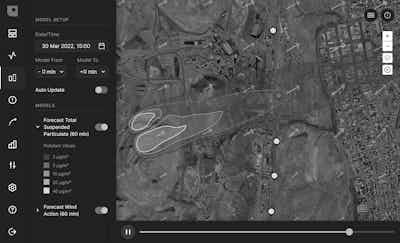

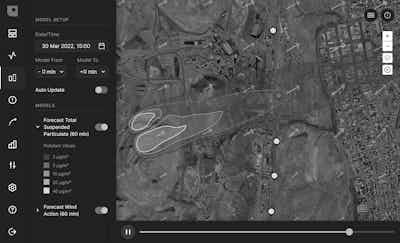

In addition to this, the EI software enabled the ground teams to mitigate site-generate emission at the mining site as well as at port operations. Utilisiing existing air quality sensors, EVS Omnis was seamlessly integrated to collect and analyse data in real-time while providing a complete situational awareness of operations.

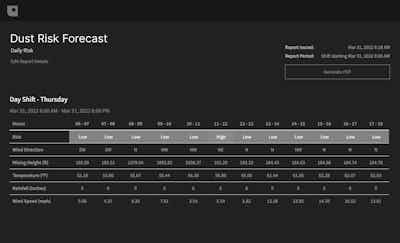

Given that the mining site is located in a tropical region, it is highly important for the operations team to forecast weather at a hyperlocal level. A key component of the solution for the coal producer is predictive risk reporting of weather and environmental factors that may impact the site such as heavy rainfall.

Results

Both the open-pit mine site and the shipping port now use EVS Omnis as an integral part of their incident response strategy. The teams can respond rapidly and effectively to potential environmental impacts before they arise, promote environmental education throughout the business and transparently communicate with stakeholders.

The EVS Omnis monitoring screens at the site’s operational control room provide situational awareness of multiple environmental parameters across the mining pit and the port. The operations team is now able to take immediate action on threshold alerts and unfolding emissions risks.

Additionally, the site management now uses predictive risk reporting in EVS Omnis as part of their operational planning to schedule mining activities while staying informed of upcoming weather conditions. The platform’s weather forecasting allows the business to plan for up to 72-hours in advance to avoid operational downtime, while also saving on resources such as water usage for mitigation of site-generated emissions.

Achieve faster responses to emissions impact.

Minimise water usage for dust suppression.

Upkeep responsible and sustainable mining practices.

Click here to download our free case study.