Water and sewerage service provision in Australia’s regional areas is typically managed by a local government authority or Council. While they share many common challenges with large specialist utilities, particularly around effective asset management and operation, scale and geographic location however can make some of these issues far more acute for a regional utility.

A local government utility typically has a smaller population and a lower rateable value; however, water and sewer services can still cover a large geographic area, leading to different asset management challenge compared to urban utilities. Managing and planning asset renewals can therefore be more challenging, often following a reactive triage approach rather than planned asset maintenance approach, which in turn can see assets being pushed beyond design life due to limited funds for renewals. This means asset condition assessment and accurate prioritisation of capital works projects become even more critical to avoid running assets to the point of failure.

Technical human resources with the experience and skills to manage asset planning can also be a major challenge for regional utilities. Salaries are commonly lower than larger urban centres including private sectors and public utilities. This can be a roadblock when attracting and retaining people with these skills. It is very common therefore for regional utilities to lean heavily on professional consulting firms to fill this skill and knowledge gap. This can be effective – yet, this also comes from the already tight capital works budget, which then also need to accommodate increased budgets for project management and delivery, adding further professional costs to the project bottom line.

Digital tools are well placed to assist regional utility engineers and operators face some of these challenges.

SeweX is a proven biological model representing the physical, chemical and biological processes in the sewer networks with the objective of predicting corrosion and odour hot-spots and allowing comparison of options for reducing impacts.

Originally developed during the SCORe (Sewer Corrosion & Odour Research) project led by the University of Queensland’s Advanced Water Management Centre (AWMC), SeweX has been used by many major Australian utilities such as Sydney Water and the City of Gold Coast. SeweX provides demonstrable outcomes in terms of identifying hot spots for odour and corrosion risks, helping utilities prioritise capital works programmes while improving operational performance with chemical dosing and ventilation modelling.

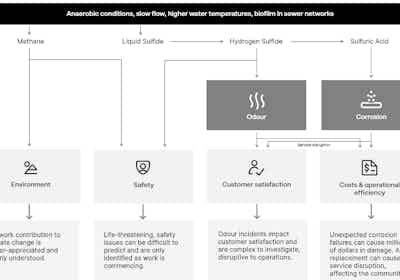

Odour, corrosion and safety risks in sewer network caused by changing weather and climate.

The changing climate and weather patterns on sewer management add further complexity for utility operators. During wet weather periods, stormwater inflow and infiltration to the sewer network can cause major issues for network operators, leading to surcharge and spills which come with both health and environmental impacts. Additionally, wet weather inflows result in high pumping and treatment costs and can trigger costly capital upgrades which otherwise could be deferred. This is the reason most utilities continually strive to reduce stormwater entry to sewers. Yet, ironically, from an odour and corrosion perspective, stormwater in the sewer helps scour the pipes and reduce sewer residence times and therefore mitigates odour and corrosion issues.

In Australia however, we are well versed in the cyclical nature of weather patterns and so as the rain comes, it will pass, and protracted dry spells will follow. The public understand water conservation well and are good at minimising water usage, particularly in dry periods, helping conserve our freshwater resources. From a wastewater perspective, conservation can have its downside with a consequential reduction in sewage quantity, resulting in a higher effluent strength which unless managed well, will generate an environment for increased corrosion, odour and safety issues in the sewer network.

Prolonged periods of drought can further exacerbate this condition as lower flows increase network residence times, favouring the anaerobic processes that drive increasing concentrations of methane and hydrogen sulphide. Both these gases present safety risks to operational staff but increased concentrations of hydrogen sulphide in particular bring increased corrosion risks and a higher likelihood of odour incidents and impacts on customers. Investigation and mitigation of odour complaints can be costly, time consuming and often involve a degree of trial and error. Repair of an unplanned sewer or manhole collapse due to unidentified corrosion can be even more costly, disrupt services and come with reputational and environmental risks also.

Traditional methods to overcome these challenges are slow and are frequently based on static models using network averages. Such methods risk missing developing corrosion issues and consequent odour and safety risks. Sewer networks include many kilometres of sewer pipes and topographical elements, such as rising mains, gravity mains, pumping stations and access points. Inspection of all these structures to identify corrosion issues is practically difficult, costly and time-consuming. Odour monitoring systems locate odours and manage customer complaints, but such processes take place after the incident has already happened and usually take substantial time and costs to investigate.

SeweX can help utilities take a pre-emptive approach to these challenges and in its new format is even more accessible to utilities and local government utilities than before.

It is easy to use and can provide local government engineers and asset planners with valuable insights into their network to help inform decisions on asset inspection programmes, prioritisation of renewals, inform odour investigation and mitigation strategies as well as model impact of new developments and additions or alterations to existing sewer networks.

Using sewer network facts, hydraulic data and wastewater characteristics as model inputs, Envirosuite’s SeweX uses predictive modelling to support evidence-based decision-making, helping engineers and planners model, identify and compare mitigation strategies which address their particular odour, corrosion or service life considerations. It does this through a network heat map for over 40 different variables, including pH, various sulphur and carbon compounds (including H2S and CH4) among others and shows how they will vary over time and across the network. Ultimately, this information results in more accurate representation of risk for capital allocation and a more effective response to odour complaints.

Digital technology can help regional utilities break down their resource barriers to manage odour, corrosion and safety risks proactively and achieve their business and strategic objectives, improve customer satisfaction and extend the working life of their assets.

About the contributor:

Sam Towndrow

Senior Process Engineer

Sam is a process engineer with over 20 years of water industry experience in both the public and private sectors. His experience spans from process design, project delivery, commissioning, operations and maintenance through to water and sewer networks as well as membrane systems in desalination and recycled water schemes. Sam brought his extensive water operational experience to his role at Envirosuite, to provide solution design, delivery and support to key clients and make sure that our technologies address operators' needs and challenges when operating desalination and water treatment plants, and sewer networks.