Customer Stories

Identifying a 23% reduction in coagulant costs with digital twin technology

A water supply department of Hong Kong implements Plant Optimiser - Envirosuite’s digital twin technology - to reduce coagulant costs at its drinking water treatment and desalination operations.

A government department in Hong Kong is responsible for providing drinking water to a population of about 7.5 million in Hong Kong and plays a critical role in the territory’s sustainable development.

Region

Industries

Platforms

in 2013 a regional government department commenced a project to expand the treatment plant. The upgraded and award-winning plant was delivered in 2018 and produces 800,000 cubic metres of quality drinking water per day for residents across multiple districts of Hong Kong.

The department has been introducing numerous advanced technologies at the treatment to continuously enhance operational efficiencies and drinking water safety

Challenge

Hong Kong is a highly developed territory with a large population of about 7.5 million people and to future-proof the territory’s water supply, the department expanded a water treatment plant in 2013. The upgraded and award-winning plant was delivered in 2018 with desalination facilities and produces 800,000 cubic metres of quality drinking water per day for residents. The department has been introducing numerous advanced technologies to enhance operational efficiencies and drinking water safety.

In 2022, the department selected Envirosuite's Plant Optimiser for its first-ever digital twin project in conventional water treatment at the Tai Po WTW to determine if digital twin technology could be applied more broadly at the plant and other similar treatment works in Hong Kong.

Solution

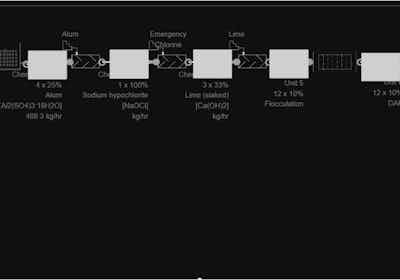

The objective of the digital twin project for the treatment plant is to use Envirosuite's Plant Optimiser technology to create a reliable model that provides actionable advice on the optimum coagulant dosage. The technology creates a digital twin model representing the coagulation, lime dosing, flocculation, and dissolved air flotation systems of the plant.

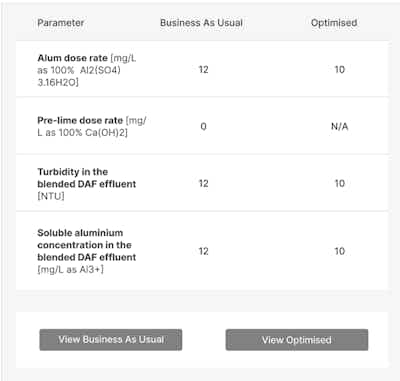

Plant Optimiser uses historical and live raw water quality and operating setpoint inputs to predict and recommend the optimal alum and lime dose every hour, along with key performance metrics such as pH, turbidity, and soluble aluminum in the blended DAF effluent. This technology aims to assist department operators in process optimization and potentially reduce the cost of coagulation while maintaining treated water quality objectives.

Result

The proof-of-concept digital twin solution was implemented in June 2022. The outputs evaluated against actual plant operations showed that the model can be used as a basis for decision making to drive down costs of operation related to alum usage, while maintaining plant operations within required bounds.

The model also identified opportunities for reduction in coagulant dosing while maintaining water quality objectives. It could therefore be applied at other similar plants or considered for expansion into other process operations at the same plant to assist operators improve performance and lower costs further.

Download our case study to find out how the drinking water treatment plant:

Identified 23.3% reduction in alum use compared to business-as-usual operations

Minimise reliance of jar tests

And ensure high quality drinking water for the local community

Click here to download our free case study.